In any mechanical system, vibration and shock are natural byproducts of moving parts. Left uncontrolled, these forces can lead to excessive noise, equipment wear, structural damage, and even complete system failure.

This is where rubber isolators come into play — offering a simple yet powerful solution to complex vibration challenges.

🔹 What Are Rubber Isolators?

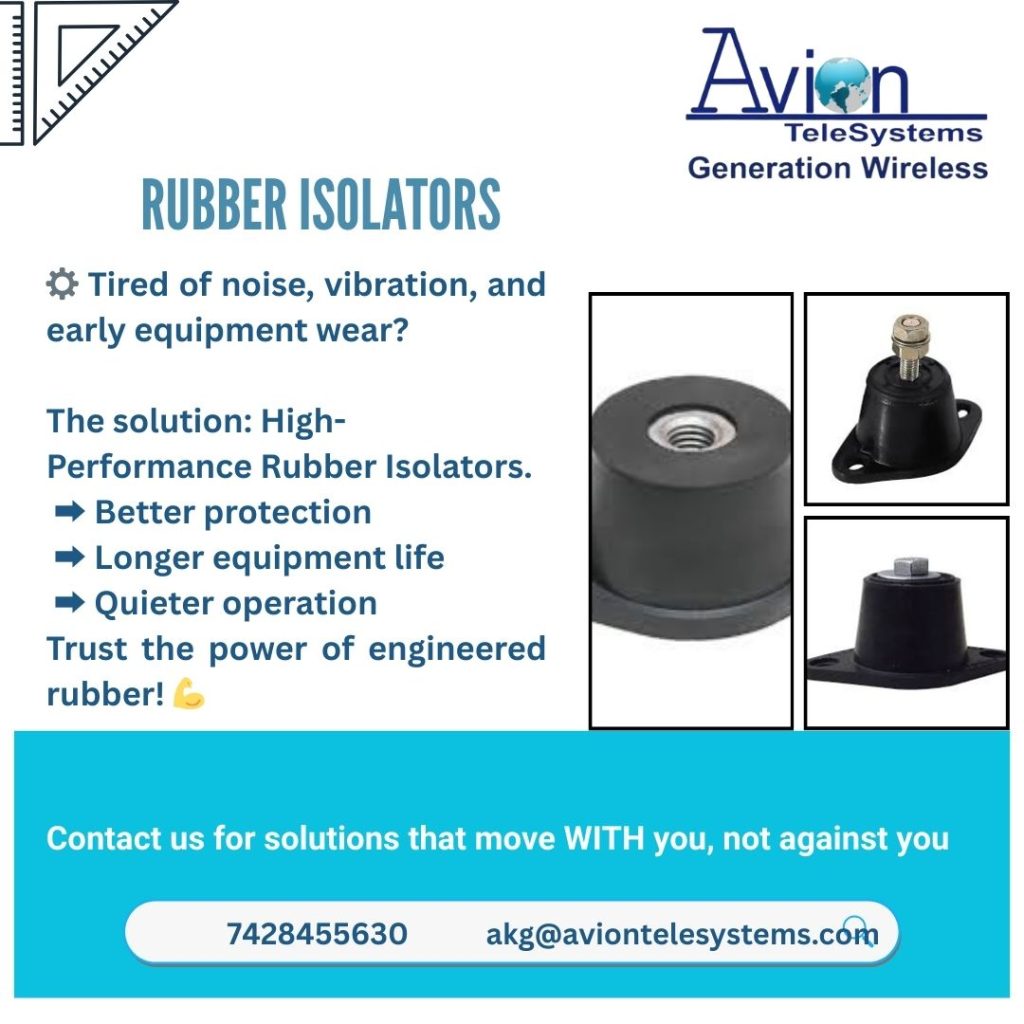

Rubber isolators are components made from specially formulated rubber materials designed to absorb and dissipate vibration, shock, and noise between two structures or devices.

They act as buffers or shock absorbers, reducing the energy transmitted through the system and protecting critical components.

Available in many shapes — such as mounts, pads, bushings, or rings — rubber isolators are widely used across industrial, automotive, electronic, aerospace, and construction sectors.

🔹 Key Functions of Rubber Isolators

✅ Vibration Damping:

They minimize the transfer of oscillations from equipment to its surroundings, improving performance and comfort.

✅ Shock Absorption:

In case of sudden impacts or operational shocks, rubber isolators absorb energy and prevent damage.

✅ Noise Reduction:

By isolating moving parts, rubber isolators significantly cut down noise levels in mechanical and industrial systems.

✅ Equipment Protection:

By reducing vibrations and impacts, isolators help prevent fatigue, cracks, and long-term mechanical failures.

Get in Touch

📞 Phone: +91 7428455630

📧 Email: akg@aviontelesystems.com

🌐 Website: www.rubberpart.in