When it comes to sealing, spacing, cushioning, and reducing vibration, rubber washers are the unsung heroes of engineering and everyday hardware. Though small in size, their impact is significant — protecting systems, extending the life of equipment, and improving performance across industries.

In this ultimate guide, we’ll dive into everything you need to know about rubber washers — including their types, common applications, and key advantages.

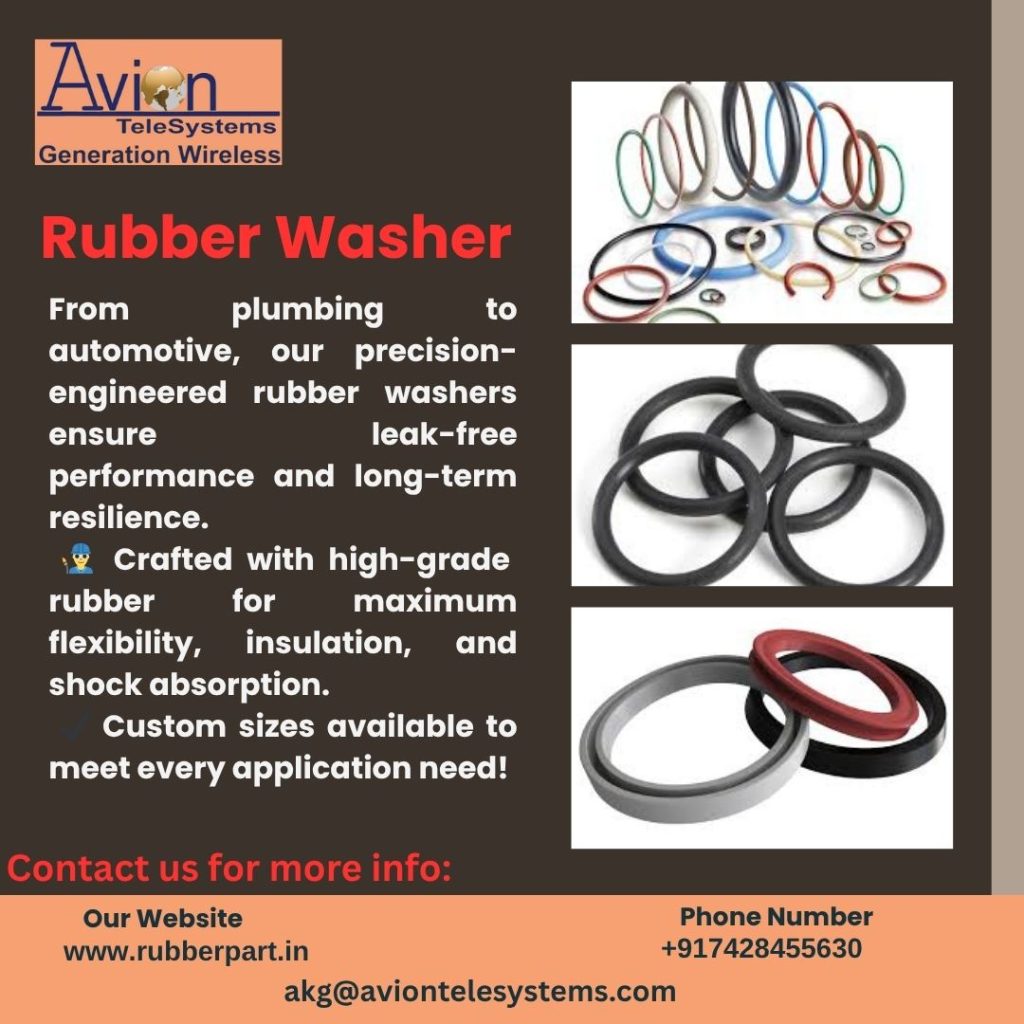

What is a Rubber Washer?

A rubber washer is a flat, disc-shaped component made from rubber or elastomeric material. It is typically used to:

- Seal joints to prevent leakage

- Absorb vibrations

- Cushion pressure between surfaces

- Electrically insulate components

Unlike metal washers, rubber washers offer flexibility and a tight seal, making them ideal for both static and dynamic assemblies.

Types of Rubber Washers

There are several types of rubber washers designed to meet specific functional needs and environments:

1. Neoprene Rubber Washers

- Resistant to oil, weather, and ozone

- Ideal for outdoor and marine applications

2. EPDM Rubber Washers

- Excellent resistance to heat, water, and steam

- Common in plumbing and solar panel systems

3. Nitrile (Buna-N) Rubber Washers

- Oil and fuel-resistant

- Widely used in automotive and industrial machines

4. Silicone Rubber Washers

- High-temperature resistance and flexibility

- Used in food processing, medical devices, and electronics

5. Natural Rubber Washers

- Great elasticity and tensile strength

- Suitable for shock absorption and cushioning

Common Uses of Rubber Washers

Rubber washers are used in countless industries and everyday products. Some of the most common uses include:

- Plumbing: To prevent leaks in faucets, pipes, and taps

- Automotive: To dampen vibrations and seal joints in engines and fuel systems

- Electronics: To provide insulation and vibration resistance in electrical enclosures

- Household Appliances: To reduce noise and wear in washing machines, dishwashers, etc.

- Aerospace & Industrial Machinery: To withstand extreme pressure and protect components

Benefits of Using Rubber Washers

✅ Leak Prevention: Creates a tight, secure seal in plumbing and hydraulic systems

✅ Shock Absorption: Protects components from damage caused by vibration or impact

✅ Corrosion Resistance: Rubber does not rust or corrode, making it ideal for wet or harsh environments

✅ Flexibility: Adapts to uneven surfaces and maintains a firm hold

✅ Noise Reduction: Acts as a buffer to minimize mechanical noise and wear

Choosing the Right Rubber Washer

When selecting a rubber washer, consider:

- Temperature resistance

- Chemical exposure

- Pressure requirements

- Size and thickness

- Compliance with industry standards (e.g., food-grade or medical-grade)

If you’re unsure which type suits your application, consulting a manufacturer or supplier can help you make the right decision.

Conclusion

Rubber washers may be small, but their contribution to sealing, insulation, and durability is enormous. From simple household plumbing to advanced industrial machinery, they ensure systems operate smoothly and efficiently.

At ATS.RubberPart, we manufacture high-quality rubber washers in various materials and custom sizes — built for performance, reliability, and long-term value.

Looking for the right washer for your application?

👉 Get in touch with us for expert support and bulk orders!

Get in Touch

📞 Phone: +91 7428455630

📧 Email: akg@aviontelesystems.com

🌐 Website: www.rubberpart.in